LCR7000 Series

Related products

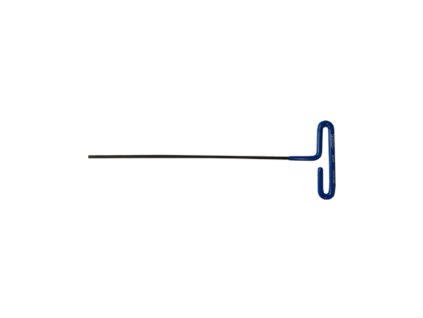

Product detailed description

LCR 7000 Series

The new LCR7000 series capillary rheometers offer many new functions and meet the requirements for 24-hour operation in the workshop while maintaining the highest possible level of accuracy, repeatability and sensitivity. The LCR series rheometers are versatile and easy to use, yet offer the most sophisticated material characterization, data analysis and reporting capabilities. The LCR series rheometers can be used with a standard tube mounted load cell and pressure transducer.

SOPHISTICATED SOFTWARE

LAB KARS ("Kayeness Advanced Rheology Software") is the most powerful and easy-to-use rheology software package for Windows™. Its easy-to-use features include: Bagley and Rabinowitsch corrections and power law, Carreau, Modified Cross and polynomial viscosity models. Using this software, users can merge multiple data files from shear stress, shear rate or thermal stability tests. The resident KARS SQC module can be used to quickly identify changes in viscosity in different batches of material. Also included is a program for correlating melt viscosity with intrinsic viscosity for PET and nylon.

REAL TIME DISPLAY

In addition to all other powerful features, LAB KARS for Windows™ provides a real-time display of force or pressure as a function of time during the test. This feature allows the operator to identify the steady state of the material flow. In addition, spikes in the force-time curve can detect contamination, unmelted resin, or bubbles in the material.

In addition to all other powerful features, LAB KARS for Windows™ provides a real-time display of force or pressure as a function of time during the test. This feature allows the operator to identify the steady state of the material flow. In addition, spikes in the force-time curve can detect contamination, unmelted resin, or bubbles in the material.

Features

■ All digital calibrations

■ larger speed and force range

■ Advanced electronics and software allow up to 45 shear stress or shear rate data points per test

■ unique algorithms for polymer melt stability

■ two-way communication allows download of test parameters from the computer

■ Multiple cylinder heating zones and adaptive PID temperature control algorithm ensure accurate and uniform heating up to 430 °C (500 °C optional for model 7000 and 7001 only).

■ Precision servo motor and transducers enable strict control of load and speed mode tests.

■ Tungsten carbide and hardened and ground tool steel body ensure long life.

■ LAB KARS, Advanced Rheology Software

LAB KARS Features

■ Bagley and Rabinowitsch Corrections

■ Carreau, Modified Cross Law, Power Law, and Polynomial Curve Fitting

■ Arrehnian temperature curve

■ Statistical error estimation

■ Dependence on shear rate

■ Dependence of time on temperature

■ Critical Shear Stress

■ Zero Shear Viscosity

■ Intrinsic Viscosity Correlation

Providing Innovative Solutions

For more than 60 years, with a commitment to helping customers, Dynisco has been providing tools and services for the polymer industry that offer its customers a 'window into the process' - an insight into the manufacturing process.

Today's customers need accurate information that allows them to verify and, if necessary, adjust their process to ensure that their products meet precise specifications. The information provided by Dynisco enables our customers to maintain a consistent process regardless of their global location.

Dynisco's portfolio represents a vast array of sensors (transducers), evaluation and display technology along with laboratory instruments with the possibility of online connection directly in production, thus providing you with the most accurate information about your production process in the market, in the field of measuring rheological properties of polymers, pressure, and temperature.

Dynisco provides our customers with the ability to compare data obtained from a pilot project with a laboratory environment with online production 24 hours a day. This data allows for immediate response and system adjustment in critical situations, ensuring that any deviations are immediately corrected to guarantee maximum quality at maximum performance.

History of Dynisco

Dynisco, known worldwide for top-notch products in pressure and temperature measurement and regulation for the plastic extrusion industry, has been developing innovative and high-quality solutions for plastic extrusion processing for 60 years and is founded on the expertise of engineers with an average of 15-20 years of experience. Dynisco's sensors, controls, and analytical instruments have proven to offer better control, reduce downtime, minimal scrap, and unmatched reliability and working life. Our commitment and ability to collaborate with you to help you measure, analyze, and equip extrusion control systems that meet your precise needs are unparalleled. From breakthrough technology in the most comprehensive range of sensors to renowned quality and performance in indicators, controls, and analytical tools.

Dynisco Sensors Dynisco was designed specifically for the robust environment of the plastics industry and has developed some of the most advanced solutions for measuring plastic extrusion, molding, and control applications. We produce a wide range of robust melt pressure sensors compatible with mV/V, mA, VDC, and HART thanks to engineering excellence based on expertise and experience.

Dynisco Analytical Instruments The quality of the process begins with the use of material. Dynisco's analytical tools enable the processor to verify material specification and optimize process conditions. These tools include flow Dynisco Heilbronn Facility in Germany

melt indexers, capillary rheometers, and small laboratory mixing extrusion systems. Dynisco also offers the most comprehensive and accurate range of on-line rheometers available on the market.

Dynisco offers a complete range of global services and technical support for our complete line. Dozens of highly qualified technical support workers are deployed internationally and provide:

Expert consultations Custom solution design On-site equipment diagnostics and troubleshooting Repairs and maintenance of transducers ∙ Installation services Equipment operation training ∙ System repairs, spare parts, preventive maintenance, and more

Customers from around the world have discovered that Dynisco is dedicated to product innovation and advanced system solutions that significantly impact the efficiency of manufacturing processes.